Lean Six Sigma (LSS) is a philosophy of doing business with focus on reducing or eliminating defects in conjunction with improving the flow in the value stream. It combines the two most important improvement trends of our time: reducing the variation of the process and making work better (using Six Sigma methodology) as well as making work faster and more efficient (using Lean principles). LSS is the most efficient problem solving methodology available. This is largely because the work done with one tool sets up another tool and very little information or work is wasted.

What is Lean Six Sigma Methodology

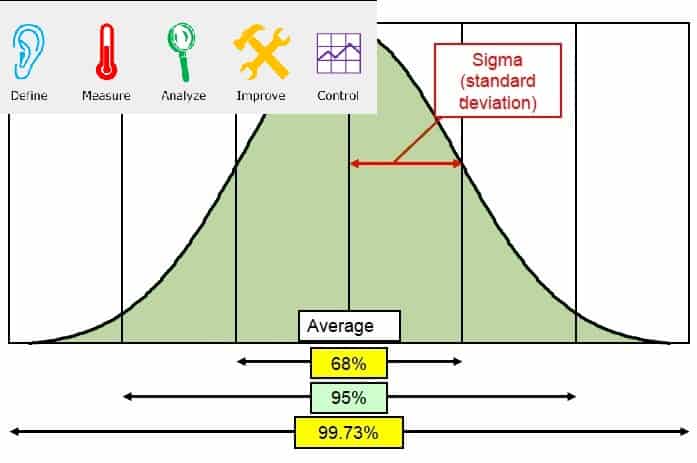

Six Sigma and Lean are toolkits to reduce waste in any kind of business process. Lean is an approach that seeks to improve flow and eliminate waste. Six Sigma uses a powerful framework (DMAIC) and statistical tools to uncover root causes in order to understand and reduce variation.

LSS methodology seeks to minimize the resources required by eliminating non-value added activities that inflate costs, lead times and inventory requirements, while emphasizing the use of quality improvement programs, preventive maintenance, pull systems, flexible work forces and flexible production facilities.

Lean Six Sigma uses the DMAIC framework (stands for – Define, Measure, Analyze, Improve and Control) for identifying and challenging poor quality, sources of waste and inefficient processes. DMAIC is a data-driven methodological approach used to systematically optimize your business processes and improve business performance.

LSS emphasizes the importance of the people side of managing change and implementing improvements that produce tangible, sustainable results and substantial returns on your investment. The final goal is to delight our customers with speed and quality, creating a rapid transformation at lower cost.

Please contact us if you require more information on training and certification or implementation and deployment within your organization or workplace.

A Little Bit of History

How Lean and Six Sigma came to be…

Toyota Production System (TPS) and Lean

After the Second World War, Taiichi Ohno was tasked with the development of a system for Toyota that would allow them to survive in the post war, extremely tough situation. The Toyota Production System was born…

Taiichi Ohno is best known for his chalk circle (Ohno circle) and the seven wastes (muda in Japanese). Among many other things, Ohno is also known for creating the Just-in-Time (JIT) model, Kanban efficiency improvement, Jidoka (autonomation) and cellular manufacturing

Since then, a variety of companies have implemented Lean manufacturing, which evolved into Lean Enterprise, a management philosophy derived mostly from the Toyota Production System (TPS). Some of the companies that successfully implemented Lean include: Intel, Nike, Kimberley-Clark Corporation, Caterpillar, Textron, Parker Hannifin, John Deere and many more.

Six Sigma

Motorola first introduced and deployed the Six Sigma methodology in its processes in the 1980’s. Motorola combined all quality management practices known until then and came up with a new quality improvement program called Six Sigma. The Six Sigma methodology is a framework that ensures excellence within the organization, with the ultimate goal that products or services have less than 3.4 defects per million.

Since then, a variety of Fortune 500 companies have gained significant financial, as well as non-financial benefits from implementing Six Sigma. Some of the companies that successfully implemented Six Sigma include: Allied Signal, General Electric, Raytheon, Bank of America, Bechtel, Amazon, 3M, Boeing, Ford, McKesson, GEICO, the US Army and Marines, Dow Chemical, DuPont, Texas Instruments, Johnson & Johnson, Honeywell and many more.

Lean Six Sigma

Since the 90’s, companies have been using Lean and Six Sigma methodologies in conjunction with each other. In the early 2000’s, organizations from around the world seem to have discovered that the integration of Lean and Six Sigma (Lean Six Sigma), is more effective and efficient towards the improvement of their business and their journey towards excellence.